- Company introduction

Company introduction

CEK 네트워크를 소개합니다.

- Business areas

Business areas

CEK 네트워크의 환경을 위한노력은 계속됩니다.

- Sustainability Management

Sustainability Management

사람과 환경을 먼저 생각하며 지속가능경영을 실천합니다.

- Customer Support

Customer Support

다양한 솔루션을 제공하도록 하겠습니다.

Business areas

Engineering

Fluid bed

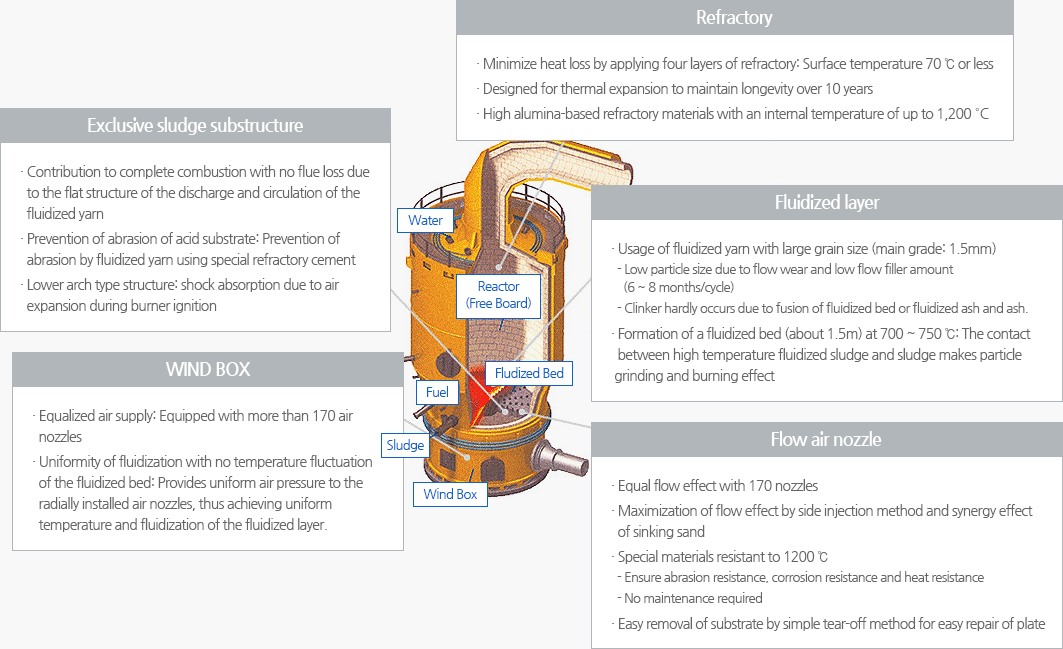

Fluidized bed incinerator structure and features

Fluidized bed incinerator facility features

The sludge is injected into the fluidized bed (sand) flowing by the combustion air fed from the furnace, and the charged sludge is broken by the heat and sand friction of 850 ° C, and is burnt instantaneously.

| Sludge input device |

|

|---|---|

| Incinerator and peripheral facility |

|

| Waste heat collecting facility |

|

| General features |

|

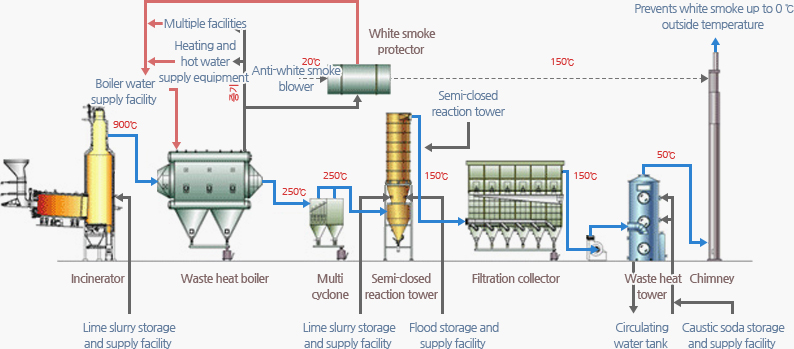

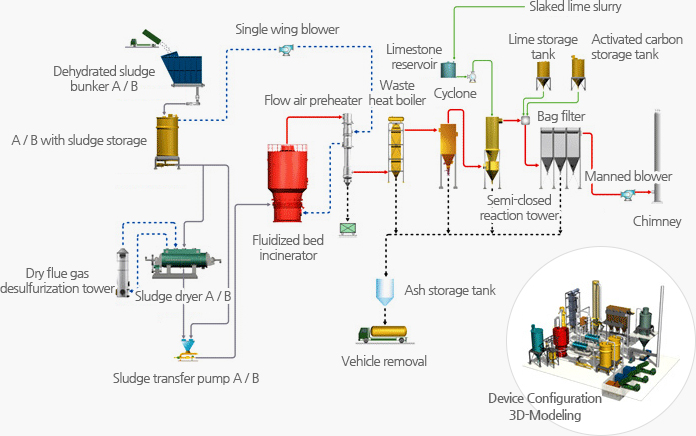

Fluidized bed incinerator flow chart

Rotary kiln

CEK NETWORK has developed Rotary Kiln Incinerator, an incinerator suitable for various types of waste incineration such as designated waste and infectious waste, in cooperation with KUREHA TECHNO ENG.

| Features |

|

|---|

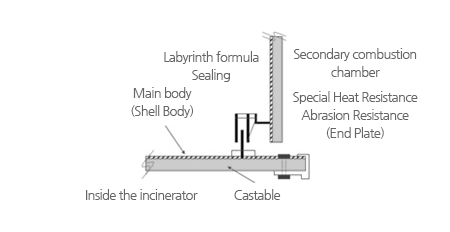

Kiln Inlet Head

Features

- · Stabilization of combustion condition by adoption of high-speed jet turning air injection system

- · Labyrinth type Air Sealing device maintains uniform operating pressure

- · Establishment of incineration ash and ash removal device

Kiln Outlet Part

Features

- · Specially designed End Plate prevents burning of refractory

- · Kiln body temperature rise prevention with cooling air injection system

Incineration process flow chart